- Mercedes In-Drive system mounts the brakes to the electric motor

- In-Drive is a friction-based braking system

- Mercedes has In-Drive in active testing, hasn’t given a timeline for production

Mercedes-Benz is rethinking how the braking system works, and where it’s located, in upcoming EVs.

In Germany last week, Mercedes-Benz engineers showed Green Car Reports one of its latest innovations dubbed In-Drive. It’s a system that relocates the entire braking system from inside the wheels to inside an EV’s electric motor housing.

The automaker didn’t commit to when, or which vehicle, the system might debut on and go into production, but it said the feature is already in active testing.

Mercedes-Benz In-Drive brake system

Mercedes-Benz In-Drive brake system

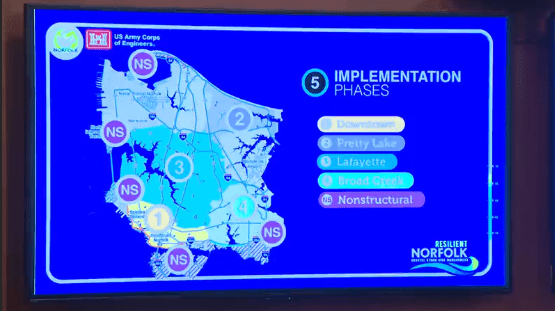

Referred to internally as “the brake of the future,” the In-Drive system is still a friction-based brake system that consists of a water-cooled brake disk that isn’t exposed to air. Mercedes engineers said they are still experimenting with different fluids. They want a lot of water in the unit to dissipate the heat, but they don’t want a giant radiator to assist. Completely enclosed, the brake discs reside on both sides of the electric motor.

Mechanical braking in EVs is only needed about 2% of the time while 98% of braking situations can be handled by regenerative braking, according to Mercedes engineers.

The new regenerative braking system in the 2026 CLA-Class, which will be the first EV on the automaker’s next-gen MMA platform, is capable of up to 200 kw of recuperation, according to Mercedes. The current EQS—a heavier car—is capable of up to 290 kw of recuperation, a Mercedes engineer said.

Mercedes-Benz In-Drive brake system

Mercedes-Benz In-Drive brake system

The Mercedes team said In-Drive is designed to be a lifetime system good for about 15 years and 186,400 miles (300,000 km), given it would theoretically only be engaged 2% of the time. Today’s brake pads only cover a small percentage of the brake disc, but the In-Drive system’s pads cover the entire surface area of the disc, which results in less force being used.

The In-Drive braking system could be mounted on a front axle that’s devoid of an electric motor, but the system would still sit in the center of the car and axle rather than by the wheels like today’s brakes.

Moving the brakes inboard shifts the weight to the center of the car and creates less unsprung mass, which will result in better handling.

By enclosing the brakes fully there’s no brake dust particulates and the wheels can be closed off to be more aerodynamic.

Mercedes-Benz paid for travel and lodging along with some German pretzels for Green Car Reports to bring you this firsthand report

Related Articles

- Mercedes developing solar paint for EVs

- Mercedes developing micro-converters for parallel wiring, mixed batteries

- 2026 Mercedes CLA will get J1772 and NACS charge ports, hybrid option

- Stellantis details 690-mile range for STLA Frame platform

- Green Car Reports expanding email newsletter